Beautiful Work Info About Is MRP A Type Of ERP

ERP Vs MRP A Helpful Guide 2025

Unraveling the Acronym Alphabet Soup

1. Understanding the Basics

Ever feel like the business world is just a giant bowl of alphabet soup? MRP, ERP, CRM—it can all get a bit dizzying. So, let's clear up a common question: Is Material Requirements Planning (MRP) a type of Enterprise Resource Planning (ERP)? The short answer? Not exactly, but they're definitely related, like cousins at a family reunion. One came before the other. MRP, the older one, primarily focuses on production planning and inventory control. ERP, the more sophisticated younger sibling, handles all aspects of a business.

Imagine a bakery. MRP helps them figure out how much flour, sugar, and eggs they need to order based on how many cakes they plan to bake. It's all about making sure the right materials are available at the right time to meet production demands. Think of it as the bakers assistant, meticulously managing the ingredient list.

Now, an ERP system for that same bakery would do all that plus manage the finances, track sales, handle customer orders, manage human resources, and even analyze marketing campaigns. Its like the entire management team, all rolled into one powerful software system. See the difference? MRP is focused and specialized, while ERP is broad and integrated.

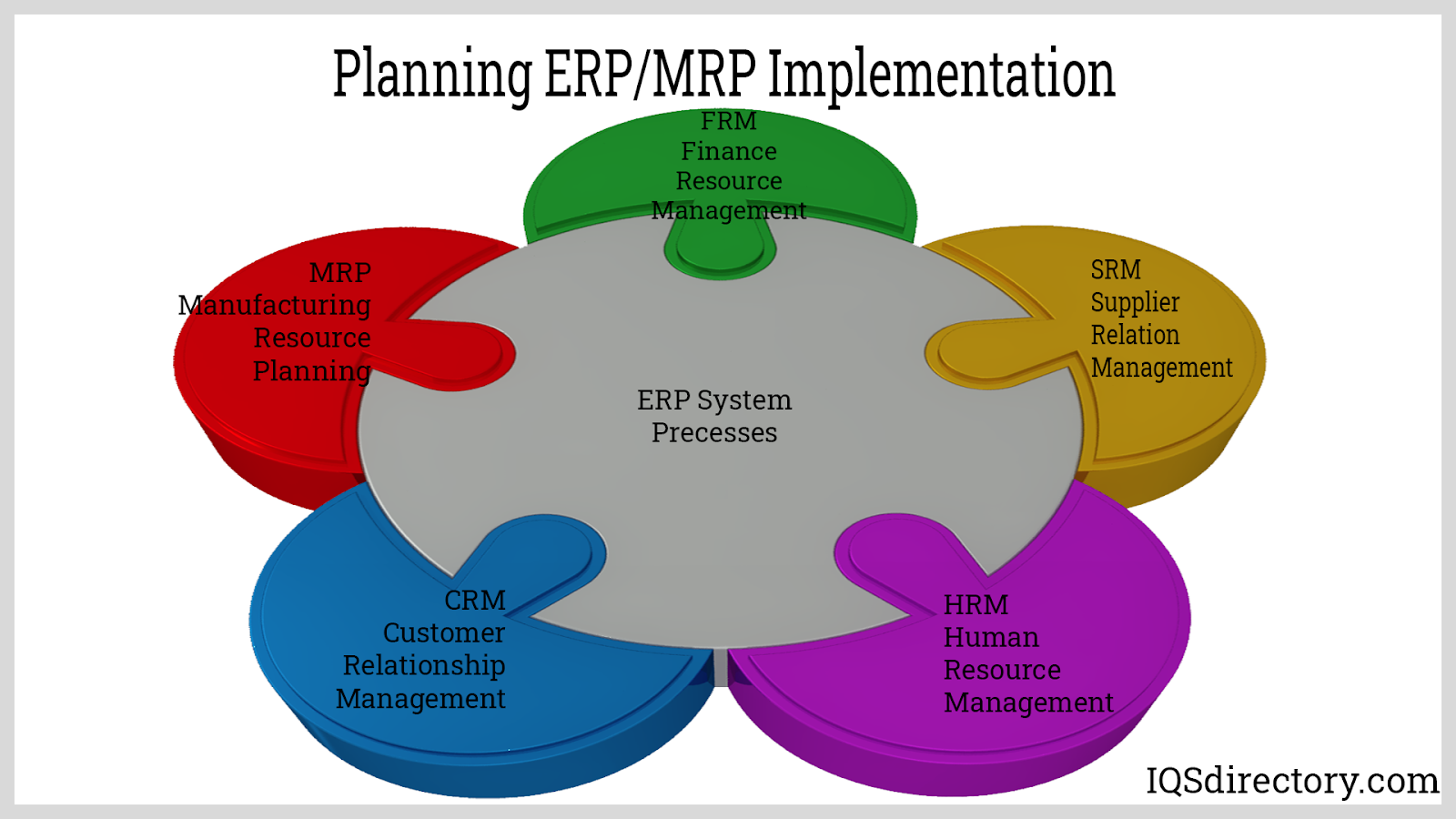

Therefore, MRP, at its core, is a component, or more accurately, a functional module, that can be found within many ERP systems. This means an ERP system might very well include MRP functionality, but also a whole bunch of other functionalities that extend far beyond just materials management. Its like saying a wheel is part of a car—true, but a car is much more than just a wheel!

Digging Deeper

2. A Historical Perspective

To fully grasp the relationship, lets take a quick trip down memory lane. MRP systems emerged in the 1960s and 70s, born out of the need to optimize manufacturing processes. Back then, computers were becoming more accessible, and businesses started using them to track inventory and schedule production more efficiently. Early MRP systems were pretty basic but they represented a huge step forward in manufacturing management.

As technology advanced, MRP evolved into MRP II (Manufacturing Resource Planning). MRP II expanded the scope of MRP to include capacity planning, shop floor control, and even some financial aspects. It became less about simply procuring materials and more about managing all the resources involved in manufacturing.

Then came ERP, in the 1990s. ERP systems took the principles of MRP II and applied them across the entire enterprise, integrating all the different departments and functions into a single, unified system. This was a game-changer, allowing businesses to break down silos and gain a holistic view of their operations.

So, MRP paved the way for MRP II, which in turn, laid the groundwork for ERP. Its a clear evolutionary path, with each stage building upon the previous one to create more comprehensive and integrated business solutions. Think of it as a caterpillar turning into a butterfly—a natural progression towards something bigger and better.

ERP Vs MRP Understanding The Key Differences

Key Differences

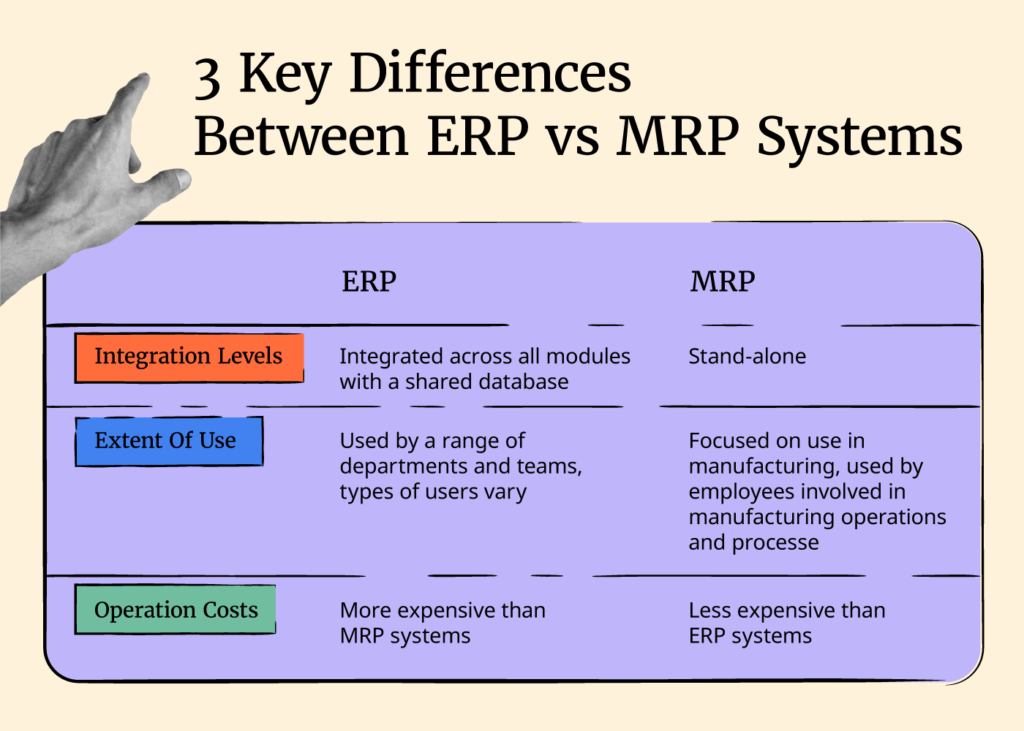

3. Comparing Capabilities

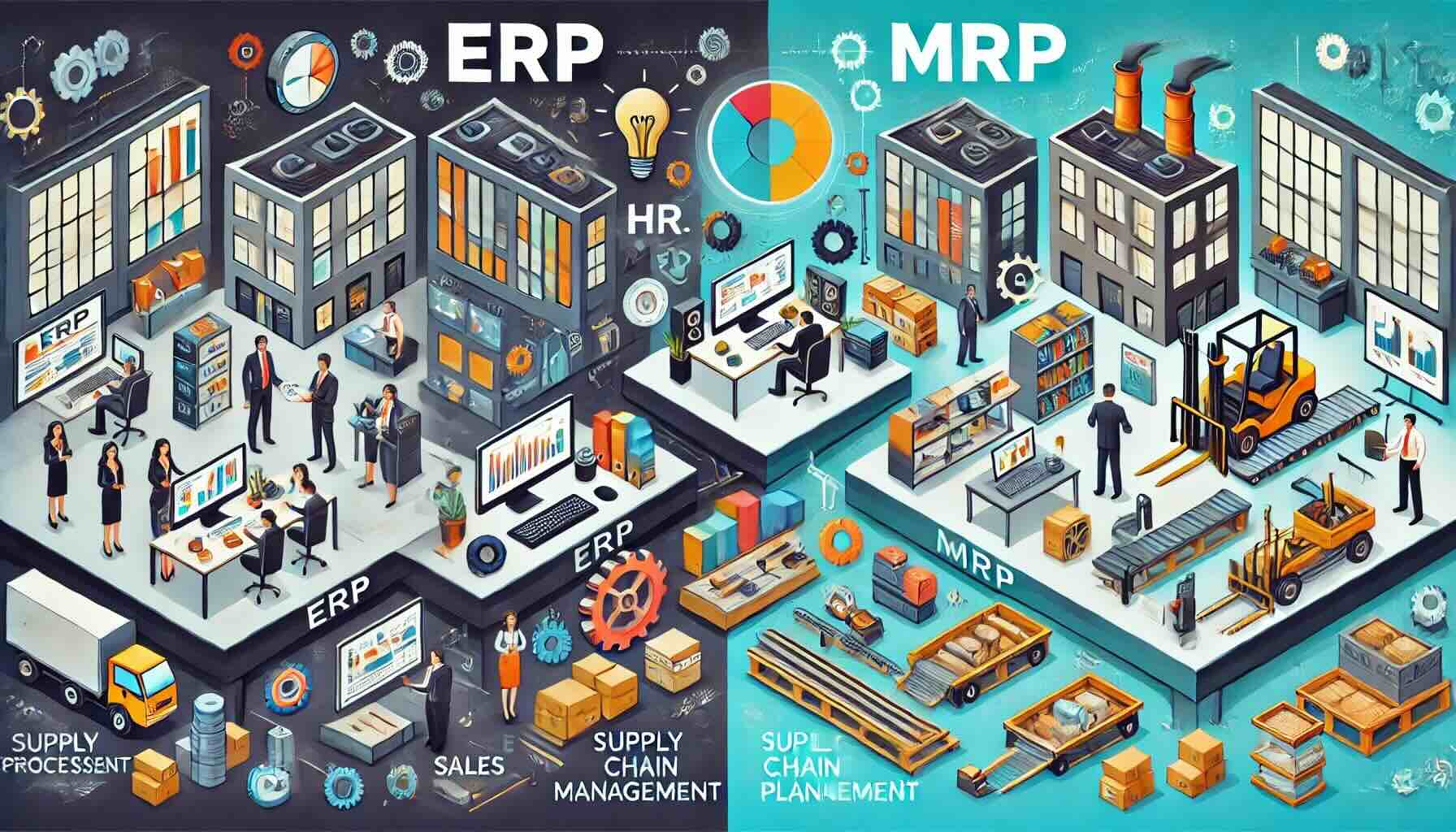

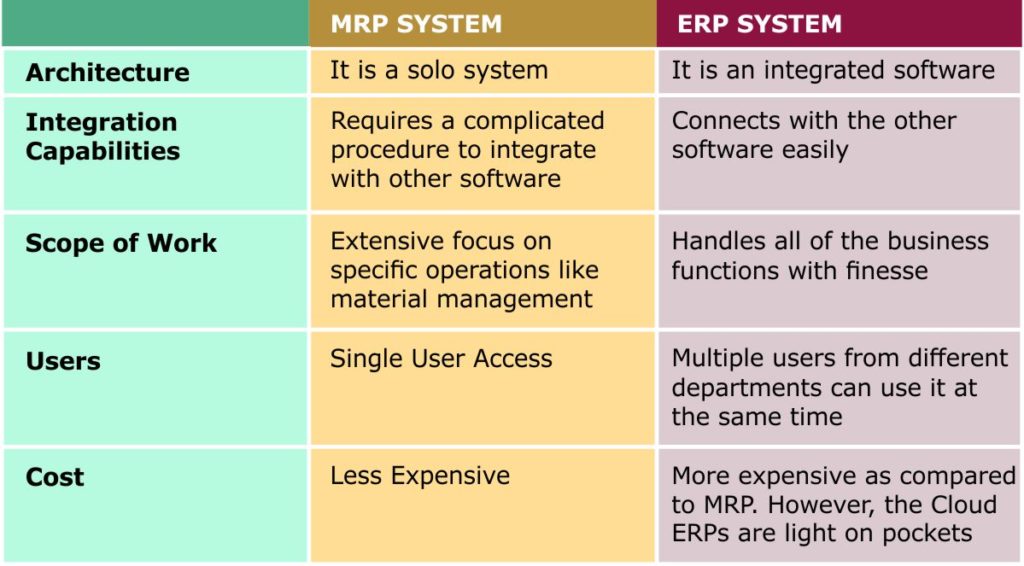

While MRP and ERP share some common ground, their functionalities differ significantly in scope and depth. Let's break down some of the key areas where they diverge. MRP is primarily concerned with ensuring that materials are available for production when needed. This includes inventory management, bill of materials (BOM) management, and production scheduling.

ERP, on the other hand, encompasses a much wider range of functions, including but not limited to: Financial Management (general ledger, accounts payable, accounts receivable), Human Resources Management (payroll, benefits administration, employee tracking), Customer Relationship Management (sales, marketing, customer service), Supply Chain Management (procurement, logistics, distribution), and Manufacturing (including MRP functionalities).

In short, MRP handles the nuts and bolts of materials planning, while ERP manages the entire enterprise, connecting all the different departments and processes. Imagine MRP as a specialized tool in a toolbox, and ERP as the entire toolbox itself, containing a variety of specialized tools for different tasks. ERP gives you the full picture, while MRP provides a focused look at the production materials aspect.

For example, with MRP alone, you can determine when to order more raw materials. But with ERP, you can also see how that purchase impacts your cash flow, how it affects your relationship with the supplier, and how it aligns with your overall business strategy. Thats the power of integration!

Benefits of ERP

4. Enhanced Efficiency and Visibility

Many businesses that start with MRP eventually transition to ERP for a number of compelling reasons. The biggest advantage of ERP is the enhanced efficiency and visibility it provides. By integrating all the different functions of the business into a single system, ERP eliminates data silos, reduces redundancies, and streamlines processes. This leads to improved decision-making, reduced costs, and increased productivity.

With ERP, data flows seamlessly between departments, providing a real-time view of the entire business. This allows managers to quickly identify and address potential problems, optimize resource allocation, and make informed decisions based on accurate information. Think of it as having a central nervous system for your business, allowing you to react quickly and effectively to changing conditions.

Furthermore, ERP systems often come with advanced analytics and reporting capabilities, enabling businesses to track key performance indicators (KPIs) and identify areas for improvement. This helps them to continuously optimize their operations and stay ahead of the competition. So, while MRP solves the specific problem of material planning, ERP offers a complete suite of solutions that support the overall growth and success of the business. Its like trading in a bicycle for a car—both can get you from point A to point B, but one offers a much more comfortable and efficient ride.

Finally, modern ERP systems are often cloud-based, offering greater flexibility and scalability compared to traditional on-premise MRP systems. Cloud ERP allows businesses to access their data from anywhere, collaborate more effectively, and scale their operations up or down as needed. This makes it a particularly attractive option for growing businesses that need a solution that can adapt to their changing needs. Who wouldn't want to access their entire business from their phone while on vacation?

Manufacturing ERP & MRP Software What Is ERP? MRP?

Choosing the Right Solution

5. Factors to Consider

So, should you choose MRP, ERP, or perhaps a hybrid approach? The answer depends on your specific business needs and circumstances. If you're a small manufacturing company with relatively simple operations, an MRP system might be sufficient. However, as your business grows and becomes more complex, you'll likely need the broader capabilities of an ERP system. Its like deciding what kind of shoes to wear—sandals might be fine for a stroll on the beach, but you'll need hiking boots for a mountain climb.

Consider factors such as the size of your business, the complexity of your operations, your growth plans, and your budget. If you have multiple departments, complex supply chains, and ambitious growth targets, an ERP system is probably the way to go. However, if you're on a tight budget and only need to focus on materials planning, MRP might be a more cost-effective option. Or, you might start with MRP and gradually add modules as needed to create a hybrid solution.

Some companies choose a hybrid approach, using MRP for manufacturing and integrating it with other standalone systems for finance, HR, and CRM. This can be a good option if you already have existing systems in place and don't want to replace them all at once. However, it's important to ensure that the different systems are properly integrated so that data can flow seamlessly between them. Because no one wants to copy and paste data all day, right?

Ultimately, the best approach is to carefully assess your business needs, evaluate the different options available, and choose the solution that best fits your requirements. Dont be afraid to ask for advice from consultants or other businesses that have already gone through the process. Choosing the right software is a big decision, so its worth doing your homework.

MRP Vs. ERP Business Software Types Subscribed.FYI

FAQ

6. Your Burning Questions Answered

Still have questions? Here are some common FAQs to further clarify the relationship between MRP and ERP.

Q: Is MRP completely outdated now that ERP exists?

A: Not at all! MRP is still a valuable tool for manufacturing companies, especially those with relatively simple operations. Many small to mid-sized businesses find that MRP meets their needs perfectly well, without the added complexity and cost of a full-blown ERP system.

Q: Can I integrate my existing MRP system with other business applications?

A: Yes, it's often possible to integrate MRP with other systems, such as accounting software or CRM. However, integration can be complex and may require custom development. A well-integrated ERP system, on the other hand, typically offers seamless integration between all its modules.

Q: What are the key benefits of upgrading from MRP to ERP?

A: The main benefits include improved efficiency, increased visibility, better decision-making, reduced costs, and enhanced customer satisfaction. ERP provides a holistic view of the entire business, allowing you to optimize processes, streamline workflows, and make informed decisions based on real-time data.

Q: Are ERP systems difficult to implement?

A: ERP implementations can be complex and time-consuming, but the benefits are well worth the effort. It's important to plan carefully, choose the right software, and work with experienced consultants to ensure a successful implementation. Also, be prepared for a bit of change management, as employees will need to adapt to the new system.

Q: How do I choose the right ERP system for my business?

A: Start by defining your business requirements, identifying your key pain points, and setting a budget. Then, research the different ERP vendors and solutions available, and ask for demos and references. Consider factors such as the software's functionality, ease of use, scalability, and vendor support.