Unbelievable Info About What Is CAN Bus Wiring

What Is A Canbus Connector At Eugene Bergeron Blog

Unraveling the Mystery

1. A Simple Explanation of a Complex System

Ever wondered how all those fancy features in your car's dashboard communicate? Or how your car 'knows' if a door is ajar? Chances are, the answer lies within something called CAN bus wiring. It sounds intimidating, maybe even a little sci-fi, but trust me, it's not rocket science. Think of it as a digital nervous system for your vehicle (or even other complex machines!).

At its core, CAN bus wiring is a standardized communication protocol. That's a fancy way of saying it's a set of rules that allows different electronic components in a system to talk to each other. Before CAN bus, every sensor, actuator, and computer needed its own dedicated wiring, leading to a tangled mess of wires, higher costs, and increased weight. Imagine the wiring harness in a classic car — now picture that multiplied tenfold, and you'll understand the problem CAN bus solves.

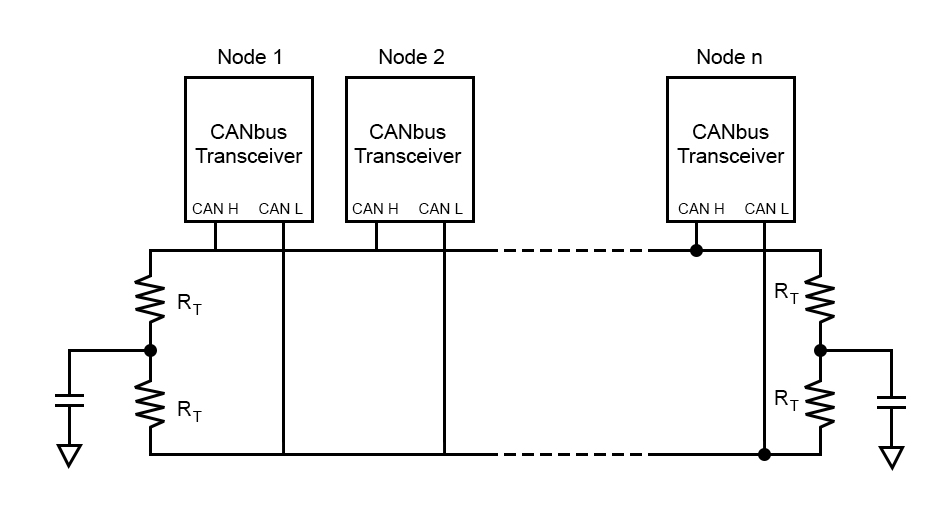

The beauty of CAN (Controller Area Network) is that it allows devices to share information over a single pair of wires (or sometimes more, depending on the system's needs). Each device on the network can 'listen' to all the messages being sent, and only responds to the messages that are relevant to it. It's like a group chat where everyone can see all the messages, but only the person being addressed replies. This significantly reduces the amount of wiring needed, making vehicles lighter, more reliable, and easier to diagnose.

So, if you hear someone talking about CAN bus wiring, just remember its the system that allows all the different electronic parts of a machine to communicate efficiently and reliably. Its a crucial component in modern vehicles and many other industrial applications, silently working in the background to keep everything running smoothly. Isn't that neat?

Delving Deeper

2. Understanding the Technicalities (Without Getting Too Technical)

Okay, now that we've covered the basic concept, let's peek under the hood a bit further. We don't need to drown in technical jargon, but understanding a few key aspects can help you appreciate how clever this system really is. CAN bus isn't just a simple wire; its about how the information is transmitted and managed. Think of it as the language and grammar spoken over that wire.

The messages sent over a CAN bus aren't addressed to specific devices by name. Instead, each message has a priority identifier. Devices on the network listen for messages with identifiers that they are programmed to recognize. This means that a device can receive the same message and react to it differently depending on its programming, or ignore it altogether if the message isn't relevant. Clever, right?

Another crucial aspect of CAN bus is its robustness. It's designed to operate in harsh environments, like the inside of a car, which can experience extreme temperatures, vibrations, and electrical noise. To combat these challenges, CAN bus uses error detection and correction mechanisms. If a message is corrupted during transmission, the receiving device can detect the error and request that the message be re-sent. This ensures that critical data is delivered accurately, even in less-than-ideal conditions.

There are also different CAN bus standards, like CAN 2.0A and CAN 2.0B, that vary in the number of bits used for the message identifier. This determines the number of unique identifiers that can be used on the network, affecting the overall complexity and capabilities of the system. Higher identifiers mean more complex system. While all this can sound complicated, the key takeaway is that CAN bus is designed for reliable and efficient communication in complex electronic systems.

The Case For Kicking CAN Bus EE Times

CAN Bus Wiring in Action

3. Beyond Cars

While CAN bus is most commonly associated with the automotive industry, its applications extend far beyond just cars and trucks. Its reliability and efficiency make it a popular choice for a wide range of industries and devices. Thinking outside the automotive box is a great way to appreciate the true versatility of this technology.

In industrial automation, CAN bus is used to connect sensors, actuators, and controllers in manufacturing plants. This allows for precise control of machinery, improved efficiency, and real-time monitoring of production processes. Imagine a robotic arm in a factory; CAN bus likely plays a role in coordinating its movements and ensuring it operates safely and efficiently.

Medical equipment also frequently relies on CAN bus for communication between different components. From sophisticated diagnostic machines to patient monitoring systems, CAN bus ensures that critical data is transmitted reliably and accurately. This is especially important in healthcare settings, where even small errors can have serious consequences.

Even in aerospace applications, CAN bus is used to manage communication between various systems on board aircraft and spacecraft. Its robustness and reliability make it a suitable choice for these demanding environments, where failure is not an option. So, the next time you're on a plane, remember that CAN bus might be helping to keep you safely in the air!

Diagnosing CAN Bus Problems

4. Troubleshooting Tips for the Digitally Challenged

Like any complex system, CAN bus wiring can sometimes experience problems. When something goes wrong, it can manifest in a variety of ways, from seemingly minor glitches to major system failures. Knowing how to diagnose these problems can save you time, money, and a whole lot of frustration. While we aren't encouraging DIY repairs (especially if you're not comfortable with electrical systems), understanding the basics can be helpful.

One of the most common symptoms of a CAN bus problem is a cascade of seemingly unrelated error codes on your car's dashboard. This happens because a single faulty sensor or module can disrupt communication on the entire network, causing other devices to report errors. It's like a domino effect, where one problem triggers a chain reaction. Pay attention to patterns or recurring errors, as these can provide valuable clues.

Another telltale sign of a CAN bus issue is intermittent or erratic behavior of electronic components. For example, your power windows might stop working randomly, or your headlights might flicker unexpectedly. These kinds of issues can be difficult to diagnose, as they may not always be present. This kind of issue can sometimes be caused by faulty wiring, loose connections, or a failing electronic module.

Diagnosing CAN bus problems often requires specialized tools and expertise. Automotive technicians typically use diagnostic scanners to read error codes, monitor data streams, and perform various tests on the CAN bus network. These scanners can provide valuable insights into the nature and location of the problem. If you suspect a CAN bus issue, it's best to consult a qualified technician who has experience working with these systems. They'll be able to accurately diagnose the problem and recommend the appropriate repairs.

Professional Wiring Of Galvanically Isolated CAN Networks

The Future of CAN Bus

5. Evolving Technologies and New Possibilities

While CAN bus has been around for decades, it's not standing still. The technology continues to evolve to meet the growing demands of modern electronic systems. New standards and innovations are constantly being developed to improve performance, increase security, and expand the range of applications. The engineers aren't simply resting on their laurels; they are constantly improving the technology.

One of the key areas of development is CAN FD (Flexible Data-Rate), which allows for much faster data transmission speeds compared to traditional CAN bus. This is becoming increasingly important as vehicles become more complex and require more bandwidth for advanced features like autonomous driving and advanced driver-assistance systems (ADAS). Imagine the amount of data that needs to be processed in real-time to enable self-driving capabilities; CAN FD helps to handle that load efficiently.

Security is another major concern for CAN bus systems, especially as vehicles become more connected to the internet. Hackers could potentially exploit vulnerabilities in the CAN bus network to gain control of vehicle systems or steal sensitive data. Therefore, researchers are working on developing more secure CAN bus protocols to prevent these types of attacks. Cybersecurity measures are now critical with how inter-connected our systems are.

Beyond automotive, CAN bus continues to find new applications in a wide range of industries. As more and more devices become connected and intelligent, the need for reliable and efficient communication networks will only grow. CAN bus, with its proven track record and ongoing development, is well-positioned to play a key role in shaping the future of connected systems.

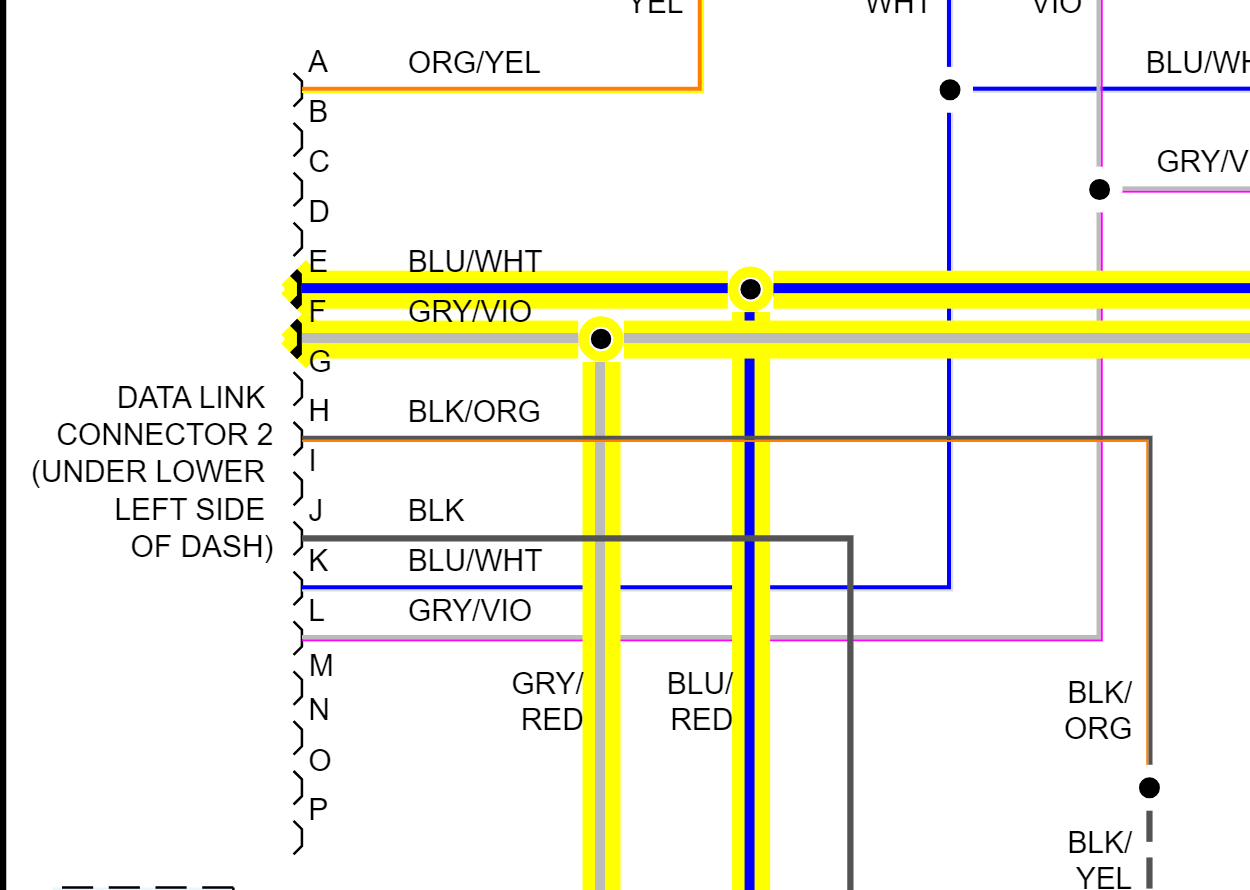

Can Bus Wiring Diagram

Frequently Asked Questions (FAQ) About CAN Bus Wiring

6. Your Burning Questions Answered

7. What exactly does 'CAN' stand for in CAN bus?

CAN stands for Controller Area Network. It's a network designed to allow microcontrollers and devices to communicate with each other in applications without a host computer.

8. Is CAN bus wiring just for cars?

No! While very common in cars, CAN bus is also used in industrial automation, medical equipment, aerospace, and many other applications where reliable communication between devices is needed.

9. Can I diagnose CAN bus problems myself?

While you can learn about the system and recognize potential symptoms, diagnosing CAN bus issues often requires specialized tools and knowledge. It's generally best left to qualified technicians.