Perfect Info About Does A PCB Replace Breadboard

Breadboard vs. PCB

1. Understanding the Basics

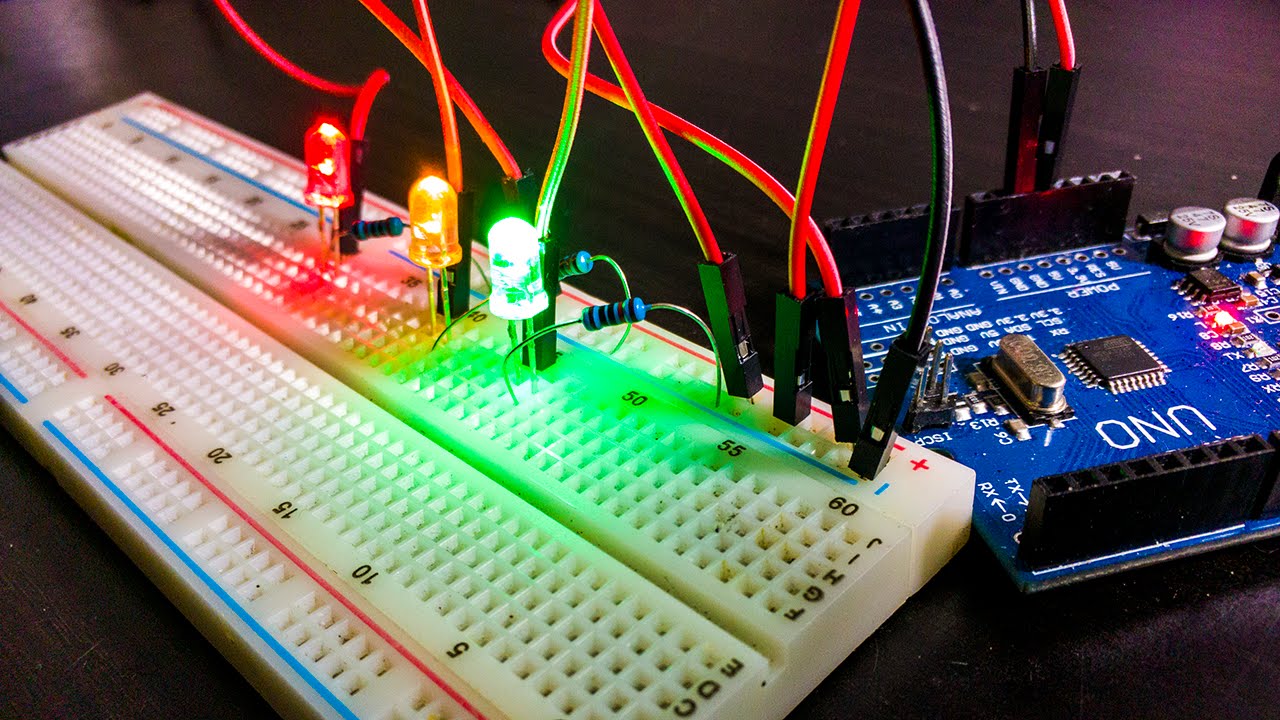

So, you're tinkering with electronics, huh? That's awesome! Let's talk about breadboards. A breadboard, sometimes called a protoboard, is your electronics playground. It's a solderless device with rows and columns of interconnected holes. You stick components in, use jumper wires to connect them, and bam! You have a circuit. Think of it as LEGOs for electronics; easy to build, easy to change, and relatively forgiving. You can quickly test out different ideas and component combinations without needing to solder anything permanently.

The beauty of a breadboard lies in its temporary nature. Need to swap a resistor? No problem! Just pull it out and plug in a new one. Trying out a different wiring configuration? Jumper wires are your best friends. This flexibility is invaluable when you're experimenting, debugging, or simply trying to wrap your head around a new circuit design. However, this temporary nature also introduces limitations, as we'll see.

Breadboards are fantastic for low-frequency circuits and for beginners who are just starting to learn electronics. The large size of the board and the relative looseness of the connections, though, can make breadboards less ideal for more complex, higher frequency applications. Imagine trying to build a sophisticated radio receiver on a breadboard; you might run into all sorts of noise and interference issues caused by the imperfect connections.

Think of breadboards as the foundation. You start there, experiment, and then, when you're ready to commit, you move on to something more permanent. They are the perfect tool for learning and experimenting without needing the commitment of soldering. Many engineers and hobbyists still use breadboards as a quick tool to test out simple or new circuits before designing the final circuit on a PCB.

2. Stepping Up

Now, let's talk Printed Circuit Boards, or PCBs. A PCB is a rigid board with conductive pathways etched onto its surface. These pathways, typically made of copper, connect various electronic components according to a specific schematic. Unlike a breadboard, a PCB is permanent — once you solder components onto it, they're pretty much there to stay (at least without some effort!).

The process of creating a PCB often involves designing the circuit layout using specialized software (like Eagle, KiCad, or Altium Designer). This software allows you to define the placement of components and the routing of the conductive traces. Once the design is complete, it's sent to a fabrication house, which uses your design to create the physical PCB.

Think of a PCB as the finished product. It is the refined, permanent version of the circuit you initially prototyped on your breadboard. Because the connections are soldered and the layout is precisely designed, PCBs offer superior performance in terms of signal integrity and reliability, especially at higher frequencies and in more complex circuits. They are also more resistant to vibration and physical stress.

PCBs are vital for most electronics we use every day, from smartphones and computers to home appliances and industrial equipment. They allow for much smaller, more efficient, and more robust designs compared to what's possible with breadboards. While PCBs require a greater upfront investment in terms of design and fabrication, they offer a significant advantage in terms of performance and durability for mass-produced devices.

Standard Permanent Breadboard Solder PCB Board Prototype

Does a PCB Replace a Breadboard? The Noun Weighs In

3. Analysing the Keyword

Here's the crux of the matter: our keyword, "PCB," is primarily a noun. This means our discussion hinges on whether one thing (a PCB) can substitute for another (a breadboard) in a given context. It's about comparing the roles and functionalities of these two components to determine if a PCB can effectively fulfill the purposes traditionally served by a breadboard.

Because "PCB" is a noun, it frames the question as a direct comparison of the object itself. We're not asking if "PCB-ing" replaces breadboarding as an activity, or if "PCB-like" materials replace breadboards. We are directly asking: can you use a PCB instead of a breadboard in all situations?

Thinking of it this way helps us realize that while a PCB can technically replace a breadboard in some scenarios, it often isn't the best or most practical choice, especially during the initial prototyping phase. The noun form of the keyword directs us to focus on the objects themselves and their innate capabilities.

The noun is very vital in this context. The answer also depends on the specific task. If you need a quick test setup, a breadboard is hard to beat. If you are looking for a permanent and reliable circuit, then a PCB is the better option.

4. Comparing Use Cases

The short answer is: not entirely. A PCB doesn't directly "replace" a breadboard in all scenarios. They serve different purposes and excel at different stages of development. A breadboard is best for prototyping, experimenting, and making quick changes to a circuit. It's like sketching out a design on paper before committing to the final blueprint.

A PCB, on the other hand, is best for creating a finalized, robust, and reliable version of a circuit. It's like taking that sketch and turning it into a solid, well-engineered structure. If you're testing out different ideas, changing components frequently, or simply learning about electronics, a breadboard is your best friend. It provides the flexibility and ease of use you need to experiment without the hassle of soldering.

However, once you've finalized your design and are ready to create a more permanent and reliable version, a PCB is the way to go. It offers better performance, greater stability, and a more professional look. It's the final step in taking your electronic creation from the drawing board to a tangible product.

So, while a PCB can theoretically function as a replacement for a breadboard, it's not always the optimal choice. The best approach is to use both tools strategically, leveraging the strengths of each at different stages of the development process. Use a breadboard for initial experimentation, and then transition to a PCB for the final, production-ready version.

5. Considering Cost and Complexity

Another key consideration is the cost and complexity involved. Breadboards are relatively inexpensive and easy to use. You can purchase a breadboard and a handful of components for a very low price, and start building circuits right away. There's no need for specialized software or manufacturing processes.

PCBs, on the other hand, require a more significant investment. You'll need to use PCB design software, which can range from free (like KiCad) to quite expensive (like Altium Designer). You'll also need to pay for the fabrication of the PCB, which can vary depending on the size, complexity, and quantity of boards you need.

This complexity can be daunting for beginners, but many resources are available to help you learn PCB design and fabrication. There are online tutorials, courses, and even communities where you can ask questions and get help from experienced designers. The benefits of using PCBs in terms of performance and reliability often outweigh the initial investment in time and resources.

In summary, breadboards are perfect for quick prototypes and learning, while PCBs excel for final products and high-performance applications. If you are experimenting with new circuits, it's usually better to start with breadboards for flexibility and affordability. Once youve ironed out all the kinks, then it's time to move to PCBs to create a more durable and production-ready circuit.

Bridging the Gap

6. Combining the Best of Both Worlds

Interestingly, there are ways to combine the advantages of both breadboards and PCBs. One common approach is to use a breadboard for the initial prototyping and then transfer the working circuit to a "proto-PCB." These are PCBs designed with a breadboard-like hole pattern, allowing you to easily transfer components from the breadboard to the PCB and solder them in place. This gives you the stability and durability of a PCB without the complexity of designing a custom board from scratch.

Another approach is to use modular electronic components and development boards, such as Arduino or Raspberry Pi. These boards often come with built-in headers that can be easily plugged into a breadboard for prototyping. Once the circuit is working, you can design a custom PCB to house the development board and any additional components you need.

This hybrid approach allows you to leverage the flexibility of breadboarding for initial experimentation while still benefiting from the performance and reliability of a PCB in the final product. It's a great way to streamline the development process and create more professional-looking prototypes.

By combining these strategies, you can find the best way to design your project from start to finish and choose the best features that breadboards and PCBs have to offer. Understanding the best time to use each method will help you avoid issues and save you time.

7. Understanding Perfboards

Perfboards, also known as prototype boards, offer a middle ground between breadboards and PCBs. They are boards with pre-drilled holes, allowing you to solder components in place and create a more permanent circuit than a breadboard. Unlike PCBs, perfboards don't have conductive traces; you need to manually connect the components using wires or solder bridges.

Perfboards are a good option for simple circuits that don't require the high performance of a PCB but need to be more durable than a breadboard. They are also useful for creating small, custom circuits that can be easily integrated into larger projects. While perfboards require soldering, they are generally easier to work with than designing and fabricating a custom PCB.

They can be very useful for smaller projects. Theyre a good first step into soldering. If you dont need a large run of circuits, perfboards are very beneficial.

Using perfboards can be a great way to develop more skills in electronics by allowing you to use a new method for connecting components.

FAQ

8. Q

A: Technically, yes, you could design and fabricate a PCB just for testing. However, it's generally overkill. The cost and time involved in creating a PCB make it much more practical to use a breadboard for initial testing and prototyping. Once you're confident that your circuit is working correctly on the breadboard, then you can move on to designing a PCB for the final version.

9. Q

A: Absolutely not! While breadboards are great for beginners because they are easy to use and don't require soldering, they are also used by experienced engineers and hobbyists for a variety of purposes. They are perfect for quick prototyping, testing new ideas, and debugging circuits. Even experienced professionals still use breadboards when they are testing out a new design.

10. Q

A: The biggest advantage of a PCB is its reliability and performance. PCBs offer much better signal integrity, lower noise, and greater stability than breadboards. They are also more resistant to vibration and physical stress, making them ideal for use in products that will be exposed to harsh environments. You can get a robust product by creating a PCB and ensure that it will be suitable for whatever use case it is needed for.

From Breadboard To PCB