Wonderful Info About What Is Broken Delta Vs Open

Delta Diagram

Understanding Open Delta and Broken Delta Connections

1. What's the Buzz About Delta Connections?

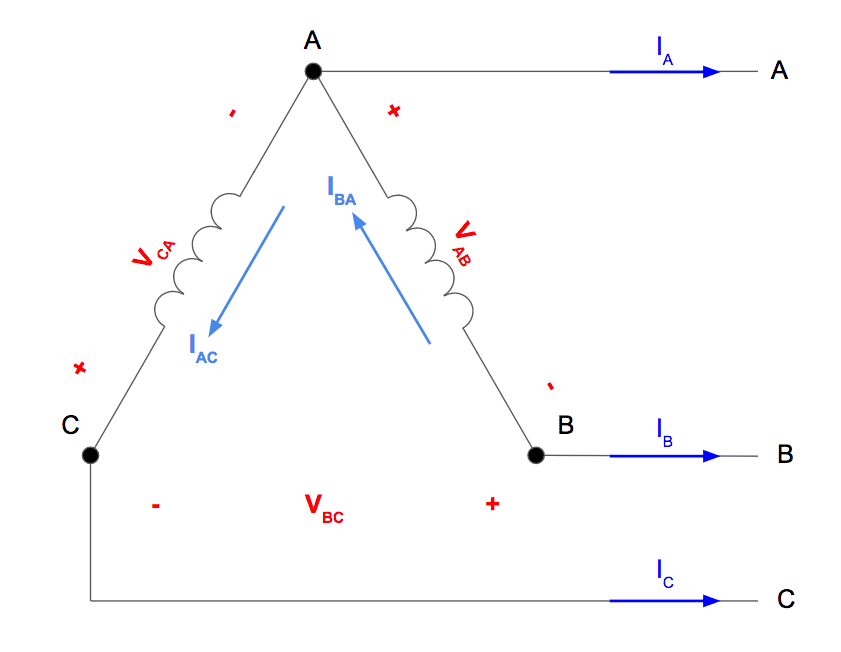

So, you've stumbled upon the terms "open delta" and "broken delta" in your electrical explorations. Don't worry, it's not some secret society handshake! It's all about how transformers are connected to deliver power. Think of transformers as the unsung heroes of our electrical grid, stepping voltage up or down to suit our needs. The "delta" part refers to a specific way three transformers are connected, forming a closed loop, kind of like a triangle. This configuration is great for supplying three-phase power, which is what many industrial and commercial applications rely on.

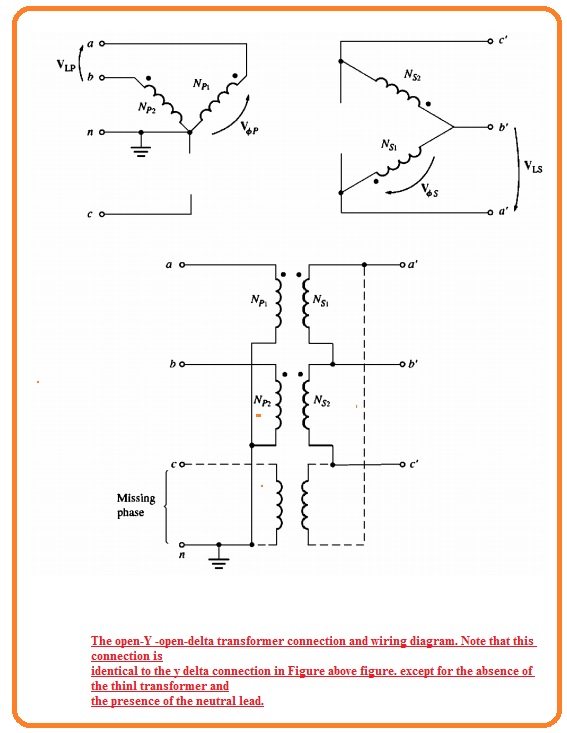

Now, the fun begins. A "full" delta connection uses all three transformers. But what happens if one goes kaput? Do we throw the whole system away? Nope! That's where open delta and broken delta configurations come into play. They're clever workarounds that allow us to keep the lights on, albeit with some limitations.

Think of it like this: imagine you have a three-legged stool. It's perfectly stable. Now, take one leg away. It's definitely not as stable, but you can still sit on it... carefully. Open and broken delta connections are similar—they're not as robust as a full delta, but they're a lifesaver in a pinch.

Before we dive deeper, lets address something crucial: The terms open delta and broken delta are often used interchangeably. While some technical nuances might exist in specific contexts, for all practical purposes, especially in general discussions, they essentially refer to the same configuration: a three-phase system powered by only two transformers.

BROKEN DELTA Vs OPEN PDF Transformer Electrical Components

Delving into Open Delta/Broken Delta

2. How Does This Two-Transformer Tango Work?

Okay, so we're down to two transformers. How do we still get three-phase power? The key is that the remaining two transformers are connected to two of the three phases, creating what looks like an open delta shape. This arrangement still provides three-phase power, but with reduced capacity. It's like having a smaller gas tank in your car; you can still drive, but you can't go as far without refueling.

The magic lies in the phase relationships. Even though we're only using two transformers, the voltage angles between the phases are maintained at 120 degrees. This is crucial for running three-phase equipment properly. However, there's a catch, and its a big one: the available power is significantly reduced. In fact, the capacity is only about 57.7% of what it would be with a full delta connection using three identical transformers. That missing transformer really makes a difference!

Imagine youre baking a cake. The full delta is like having a powerful stand mixer, effortlessly whipping up the batter. The open/broken delta is like having to mix it by hand. Youll still get a cake, but it will take more effort, and maybe the result wont be quite asfluffy.

Therefore, these configurations are generally used as temporary solutions, such as during transformer maintenance or in situations where the load requirements are relatively small. Nobody wants to run a whole factory on an open delta connection for extended periods. Its like trying to run a marathon on a single energy bar possible, but not ideal!

Why Use an Open Delta/Broken Delta Connection? The Upsides and Downsides

3. When Is This a Good Idea (and When Is It a Terrible One)?

So, what are the reasons for using this configuration? The primary reason is redundancy. If one transformer fails in a full delta connection, switching to an open delta configuration allows you to continue operating, albeit at a reduced capacity, until the faulty transformer is replaced. This prevents a complete shutdown, which can be costly and disruptive.

Another reason might be cost savings, at least initially. If you anticipate a future increase in power demand, you could start with an open delta configuration using two transformers and add the third transformer later when needed. This allows you to spread out the investment over time. However, keep in mind that this is only a temporary solution, and you'll eventually need that third transformer to meet growing demands.

However, there are significant drawbacks. The reduced capacity, as mentioned earlier, is a major limitation. Also, open delta connections can lead to voltage imbalances and increased harmonic distortion, which can damage sensitive equipment. Think of it like driving a car with misaligned wheels; it might work for a while, but it'll eventually cause problems. For example, you should never use an open delta configuration when dealing with rectifiers, variable-frequency drives, or other applications that introduce a lot of harmonics, as these can severely impact equipment operations.

So, the key takeaway is this: open delta configurations are a temporary fix, not a long-term solution. They're like a band-aid on a broken leg; it'll keep you going for a short while, but you'll eventually need proper medical attention (i.e., a full delta connection) to get back to full strength.

What Is The Purpose For Open Delta Connection In Potential Transformer

Applications of Open Delta/Broken Delta

4. Spotting the Open Delta in the Wild

Where might you encounter these open delta configurations? They're often used in rural areas where the power demand is relatively low and a full three-phase system isn't initially required. Think of small workshops, agricultural facilities, or even some residential areas. In these cases, an open delta connection can provide a cost-effective way to supply three-phase power for specific equipment, like pumps or motors.

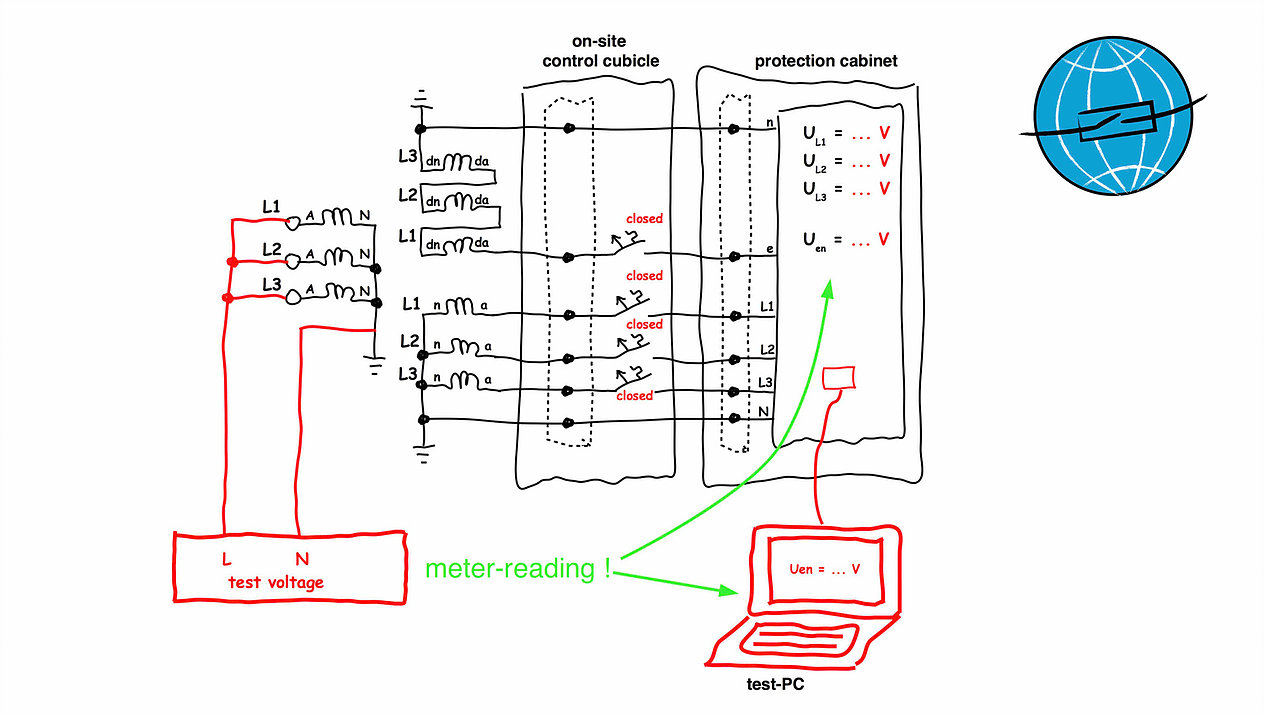

Another common application is in backup power systems. If a transformer in a full delta connection fails, an open delta configuration can be quickly implemented to restore power to critical loads until a replacement transformer arrives. This is particularly important in industries where even a brief power outage can have significant consequences, such as hospitals or data centers.

You might also find them during construction or maintenance work. An open delta connection can provide temporary power to construction sites or allow for the safe replacement of a transformer in a full delta system without completely shutting down power to the entire facility. These are like temporary power plants or substations to enable the continuous operation of key functions.

Ultimately, it's about balancing cost, reliability, and power requirements. While a full delta connection is generally the preferred option for most applications, open delta configurations offer a valuable alternative in situations where redundancy, cost savings, or temporary power solutions are paramount.

Delta Transformer Wiring Diagram

The Future of Delta Connections

5. What's Next for Power Distribution?

The world of power distribution is constantly evolving, and while the fundamental principles of delta connections remain the same, new technologies and innovations are shaping their future. Smart grids, for example, are becoming increasingly prevalent, incorporating advanced monitoring and control systems that can optimize the performance of delta-connected transformers and improve overall grid efficiency.

Another trend is the increasing use of solid-state transformers (SSTs), which offer several advantages over traditional oil-filled transformers, including smaller size, lighter weight, and improved efficiency. SSTs can be configured in delta connections and offer greater flexibility in power distribution systems. However, SSTs are still relatively expensive compared to traditional transformers, so their adoption has been gradual.

As renewable energy sources, such as solar and wind power, become more widespread, the need for flexible and reliable power distribution systems is growing. Delta connections play a crucial role in integrating these renewable sources into the grid and ensuring a stable power supply. In this new landscape, understanding the specific challenges and benefits of each type of electrical configuration is more important than ever.

Whether its an open or a closed delta, these connection configurations will continue to be used in countless different ways. Their ongoing innovation and incorporation into modern electrical grids will allow engineers and electricians to deliver more sustainable and reliable power to more and more people.

FAQs About Open Delta and Broken Delta Connections

6. Your Burning Questions Answered

Still scratching your head? Let's tackle some frequently asked questions:

Q: Can I run a large motor on an open delta connection?A: It depends on the motor's horsepower and the capacity of the open delta system. Large motors require significant starting current, which can overload the system and cause voltage sags. It's best to consult with an electrical engineer to determine if an open delta connection is suitable for your specific motor.

Q: Is an open delta connection more efficient than a full delta connection?A: No, a full delta connection is generally more efficient. An open delta connection has higher losses due to the unbalanced currents and increased harmonic distortion.

Q: How do I convert an open delta connection to a full delta connection?A: You'll need to add a third transformer to complete the delta configuration. Ensure that the transformer is properly sized and connected to the correct phases. It's also recommended to have a qualified electrician perform the conversion to ensure safety and proper operation.